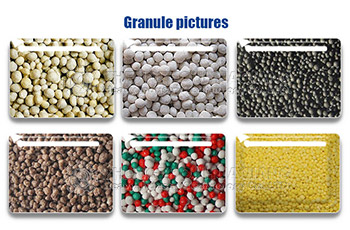

NPK compound fertilizer granulation production linePosted by Organic Fertilizer Machinery on June 15th, 2019 NPK compound fertilizer has the advantages of good appearance, high fertilizer efficiency, uniform coating and strong wear resistance. It can provide sulfur nutrition after degradation of the film, and is pollution-free, which meets the requirements of environmentally friendly fertilizer. NPK compound fertilizer has various kinds of slow-release fertilizers and processing forms. This NPK compound fertilizer production line adopts the method of coating, including sulfur coating, resin coating and so on. A large number of field fertilizer efficiency experiments have proved that compared with non-coated fertilizer, the yield can be increased by 6-10% at the same level of economic input. At the same yield level, the amount of fertilizer application can be reduced by 1/3 and the utilization rate of fertilizer can be increased by 10%. In terms of ecological and environmental benefits, NPK compound fertilizer can effectively reduce the impact of nitrate content in groundwater, reduce eutrophication caused by water pollution, and improve the safety and quality of agricultural products. Equipment feature of NPK compound fertilizer production line Rotary drum granulator used for hot and cold granulation and high, medium and low concentrations of mass production of compound fertilizer. It has the feature of high pelletizing rate, high strength of round particles. The machine shell adopts special rubber or acid-resistant stainless steel lining. The raw materials are not easy to bond to the cylinder wall and play an anti-corrosion role. The drum granulator has large output, good economic benefit and resource saving.

Drum Dryer Machine

In order to improve the productivity of the dryer machine, the larger diameter and length of the dryer are usually chosen to increase the effective volume of the drum, and prolong the drying time of the material. Dryer machine of different specifications must be equipped with corresponding oil (gas) fired stove and draft fans with corresponding air volume. Feature 1. NPK compound fertilizer dryer machine has a high degree of mechanization, a large production capacity, and can run continuously. 2. The structure of NPK compound fertilizer dryer machine is excellent and simple. The material runs smoothly through the barrel resistance and is easy to operate. 3. NPK compound fertilizer dryer machine has less malfunction, low maintenance cost and low power consumption. 4. NPK compound fertilizer dryer machine has wide application range and good drying uniformity. Rotary Drum Screener Rotary drum screener machine is common equipment in fertilizer production, mainly used for separating the returned materials and finished granules, realize the classification of the end products, and even classify the end products. The drum screener machine mainly includes the frame, classification chamber, sieving rotor structure, a main reducer and a main motor. Rotary drum screener machine is common equipment in fertilizer production, mainly used for separating the returned materials and finished granules, realize the classification of the end products, and even classify the end products. The drum screener machine mainly includes the frame, classification chamber, sieving rotor structure, a main reducer and a main motor.

Like it? Share it!More by this author |