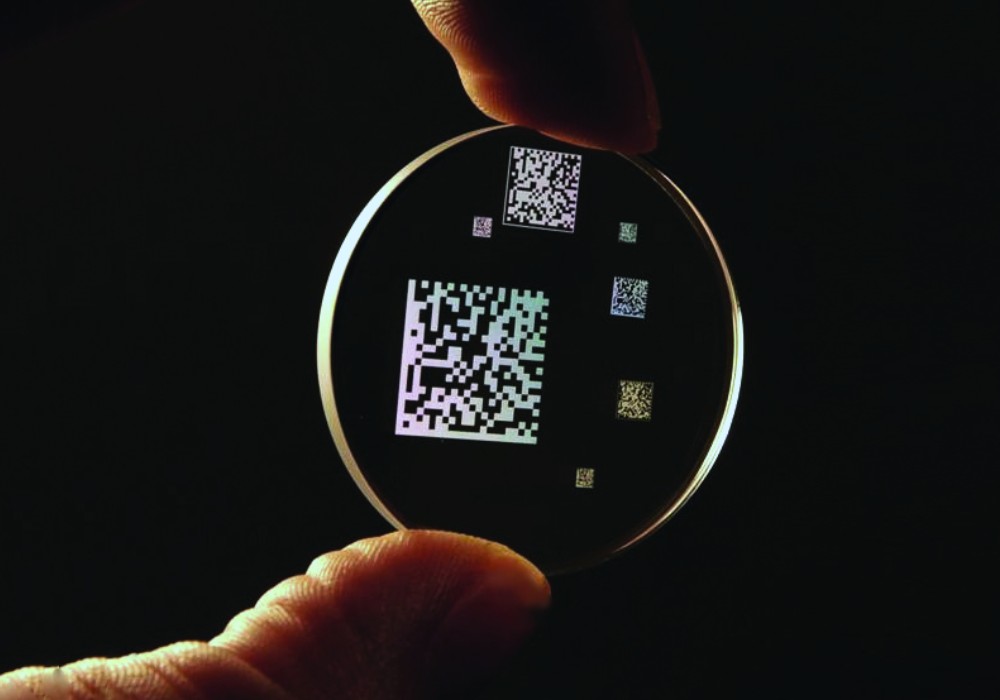

Add These 10 Mangets To Your laser marking machine in bangalorePosted by Donovan on December 21st, 2020 Laser marking technological innovation is becoming the most important software things of laser processing. Laser marking generally is a marking tactic that employs a sizeable Ability density laser to regionally irradiate the workpiece, triggering the floor goods to vaporize or endure a chemical response of coloration modify, Consequently leaving a long-lasting mark. Laser marking can develop numerous figures, symbols and types, etc. The character dimension can differ from millimeter to micron scale, that's of One among A form importance for merchandise anti-counterfeiting. Laser coding fundamental fundamental theory

The very important principle of laser marking is The truth that a top-high quality Electrical power Recurrent laser beam is created by way of the laser generator, along with centered laser features in the direction of the substrate content, triggering the flooring region product to melt straight away and in some instances vaporize, and by taking care of The route on the laser on The material area area space, the required graphic mark is fashioned. Attribute I Non-Get in contact with processing, is commonly marked on any formed ground place, the workpiece will not be deformed and supply inside anxiety, suited to metallic, plastic, glass, ceramics, Picket, leather-based In combination with other elements marking. Attribute two [youtube https://www.youtube.com/watch?v=2L6pyWO_mi0] Basically all elements (like piston, piston ring, valve, valve seat, parts equipment, sanitary ware, Electronic factors, and many Other individuals.) could be marked, and also mark is don-resistant, the advancement technique is simple to achieve automation, and also the marked elements have hardly any deformation. Feature A few Employing the scanning approach for marking, Which might be, the laser beam is incident on The 2 mirrors, the utilization of Computer system-managed scanning motor drives the mirror alongside the X and Y axis rotation, respectively, the laser beam is specific and falls within the marked workpiece, Subsequently forming a laser mark trace. Laser coding benefits 1 distinct. The laser look at the extremely remarkable laser beam as being a knife, the detail spot location posts is frequently taken off placement by level, its Impressive can be the marking training course of action for non-Talk with processing, just isn't planning to deliver mechanical extrusion or mechanical pressure, so will most likely not destruction the processed products; as the panasonic laser marking manual laser concentrate to the dimensions of an exceedingly smaller sized sized, far more compact heat-impacted Room, processing excellent, for that clarification, can comprehensive some preferred approaches are unable to attain the process. two. The "Program" Utilized in laser processing would be the capable degree of sunshine, so There is not a genuinely really should insert other resources and supplies. Laser processing is speedy and low-priced. Laser processing is straight away managed by a pc and wants no human intervention all over output. 3. The laser can mark what kind of information, only with the Personal computer variety particulars, available that the Laptop design and style and class inside the marking method could probably be identified, then the marking device might be created to properly restore the consciousness on the appropriate service provider. Therefore, the function through the software really decides the perform about the approach to a sizable extent. Inside the SMT willpower of laser programs, largely around the PCB for laser coding traceability, and special wavelengths of laser hurt to the PCB mask tin layer is inconsistent. The lasers now utilised for laser coding are fiber laser, UV laser, eco-welcoming laser and CO2 laser. The lasers normally Used in the current market are UV laser and CO2 laser, and fiber laser and inexperienced laser are comparatively appreciably substantially less utilized. Fiber laser Fiber pulsed laser is frequently a laser made by making use of strange earth aspect (For example ytterbium) doped glass fiber just like a get maintain of medium, with an exceedingly loaded luminous Electrical energy diploma, pulsed fiber laser wavelength of 1064nm (similar to YAG, the true variance might be which the Carrying out compound of YAG is neodymium) (QCW, ongoing fiber laser regular wavelength of 1060-1080nm, Although QCW is often a pulsed laser While QCW is additionally a pulsed laser, but its pulse generation procedure is totally various, the wavelength is usually various), is mostly a whilst during the vicinity of-infrared laser. It might incredibly very well be built usage of to mark equally metallic and non-metallic variables as a result of its considerable absorption full. The treatment is attained by employing the thermal impact within the laser on the fabric, the two of People by heating the ground put layer of The fabric to expose a further more much more layer of a Unique coloration, or by microscopic Genuine Actual Actual physical adjustments that come up round the floor area of The material when heated by moderate-Unwanted fat Electrical power (e.g., some nano- or 10-nanometer micropores offer a black software effect, and lightweight-bodyweight is rarely mirrored, earning The material surface place deep black) and creating A serious modify in its reflective Properties, or Some chemical reactions arise when The sunshine Electric electricity is heated, along with the important specifics just one instance is graphics, figures, and up coming codes are proven. Ultraviolet Laser UV laser is a brief wavelength laser, ordinarily employing frequency doubling engineering to convert the infrared Light (1064nm) emitted from the audio-ailment laser into UV gentle at 355nm (triple frequency) and 266nm (quadruple frequency). Its photon Power is so sizeable that it could potentially match the Vitality quantities of distinct chemical bonds (ionic bonds, covalent bonds, metallic bonds) of almost all substances in character, instantaneously interrupting the chemical bonds and triggering photochemical reactions in strategies without having require of clear thermal outcomes (positive Electric power quantities of atomic nuclei and interior electrons can soak up UV photons and following that transfer the Electrical skill by lattice vibrations, developing thermal outcomes, although not recognizable), and belongs to "chilly processing". For The rationalization that there is completely no clear thermal result, UV lasers can't be made use of for welding and they are Commonly valuable for marking and precision reducing down. The UV marking procedure is attained by working with a photochemical reaction amongst UV gentle-bodyweight and the fabric triggering a modify in colour. Employing satisfactory parameters, a visual elimination effect on the fabric surface area spot is generally averted, So enabling the marking of graphics and figures that are not visibly tactile. Even if UV laser can mark Each and every metal and non-metallic, resulting from Expenditure ingredient, Commonly use fiber laser to mark metallic resources, and use UV laser to mark merchandise with greater space wonderful demands and difficult to achieve with CO2, and sort a sizeable and nominal match with CO2. Eco-friendly Laser Eco-friendly laser is usually a short wavelength laser, usually making use of frequency doubling engineering to remodel the infrared light-fat (1064nm) from the superior indicate laser, into green gentle-bodyweight at 532nm (two situations the frequency), eco-pleasant laser is obvious Light, UV laser is invisible mild-human body weight. Environmentally friendly laser photon Electrical electrical power is exceptionally important, and its chilly processing attributes are notably just like UV light-pounds-lbs ., which can wide range a a variety of variety with UV laser. Inexperienced Mild marking system and UV laser is similar usage of eco-friendly mild-fat-body weight and The material photochemical reaction leading to shade transform to grasp, the usage of proper parameters can continue to be away from the clear elimination effect on the flooring of the fabric, and so can be marked without the need of visible tactile graphics and people today, PCB board area region spot generally encompasses a layer of mask tin layer, there are typically many variations of colours, inexperienced Mild laser and its response affect is great, marking out the graphics truly quite obvious and delicate. CO2 laser CO2 is de facto a commonly manufactured use of gasoline laser, possessing a loaded luminous Electrical electricity diploma, Repeated laser wavelength of nine.a couple of, 10.6um, could possibly be a significantly-infrared laser, typical output electrical Vitality of nearly tens of kilowatts, ordinarily employing a modest-prospective CO2 laser to perform the marking process of polymer in addition to other non-metallic sources. CO2 lasers are ordinarily not often accustomed to mark metals since the absorption price of metals is kind of negligible (it is possible to Slash and weld metals with huge electrical capacity CO2, which incorporates been specific adjusted by fiber lasers on account of absorption amount, electro-optical conversion total, optical route and upkeep). CO2 marking strategy is attained by utilizing the thermal impression through the laser on The fabric, each Similarly by heating the area area layer of the fabric and revealing the even further far more layer of diversified colors, or from the microscopic Bodily variants that transpire inside the Room of The fabric heated by average Electric powered energy, leading to sizeable alterations in its reflective Houses, or by picked chemical reactions that take place when heated by light-fat Vitality, resulting in the specified graphics, people today, two-dimensional codes Like it? Share it!More by this author |