High Performance Carbide Cutter From XYMJPosted by summer on February 8th, 2021 Tungsten carbide cutter plays an extremely important role in the machining process because it offers higher wear resistance than high-speed steel, which can withstand higher working temperatures and can be very well optimized to meet the requirements of various processes. At the cutting edge, carbide tools can withstand temperatures of up to 1,100°C with minimal creep, with higher cutting speeds and feed rates. The tungsten carbide provides minimum quantity lubrication and high-speed cutting, which can meet high demands for the performance of cutting tools. According to the shapes of customized tungsten carbide cutting tools, the cutting tools are classified into round blades, ring blades, long blades, arc blades, toothed blades, trapezoidal blades, wave blades, serrated blades, disc blades, and special-shaped blades, etc. Why Choose Tungsten Carbide Cutting Tools Cost-effective Carbide (either tungsten or titanium) is much better at dissipating heat than steel. Thus, when using these tools, you don’t have to stop as often to allow the machinery to cool off. Also, this dissipation helps the material stay stronger because it doesn’t change the structure of the metal. It has a long service life. Cleaner Cuts and Finishes One crucial element of a carbide cutting tool is that the edge is going to stay sharper for longer. Because it maintains a sharper edge, that also means that you get a cleaner, neater finish. Whether cutting hardwood or metal, having cleaner results will save you both time and money. Carbide tools don’t damage the grain as much either. Long Service Life When you combine the durability of steel with the expert finishing power of carbide, you get a tool that is built to last. Tungsten Carbide Rotary Burr

Tungsten carbide rotary burrs, also known as rotary files or die grinder bits are used for cutting, shaping, and grinding, and applicable for the removal of sharp edges, burrs and excess material. They provide high precision cutting. Tools, such as burrs, made from carbide, can withstand higher temperatures and maintain a sharper cutting edge than high strength steel. Carbide rotary burrs have been used widely in shipping construction, auto engine porting and foundry fabrication. With its high rotating speed and hardness, it can machine a lot of different materials, such as cast iron, carbon steel, alloy steel and non-ferrous material. High life service of product is warranted for virgin and excellent raw material which is one of most critical factors to the carbide burr's life. Tungsten Carbide Circular Blade

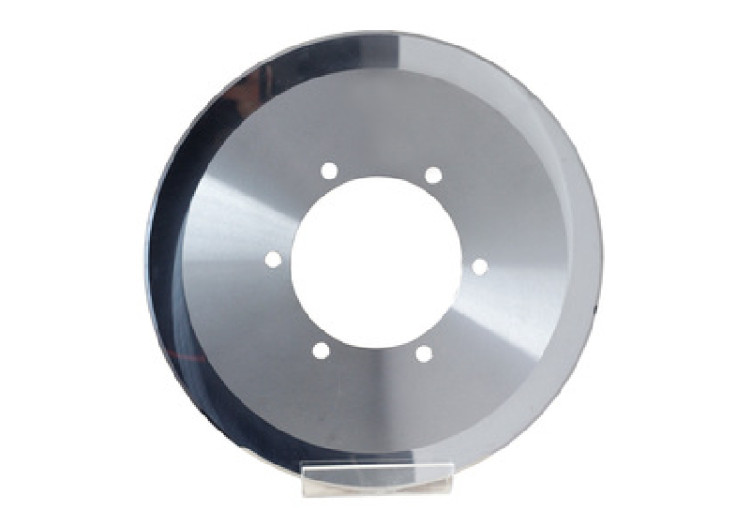

According to the applicable Industry of the carbide cutting tools, the carbide circular blade can be classified into printing industry blades, paper industry blades, aluminum foil blades, metal film cutting blades, medical blades, car care blades, tobacco cutting blades, packaging blades, food blades, film blades, leather blades, rubber points Cutting blades, chemical fiber/glass fiber blades, textile machinery blades, plastic blades, feed blades, paper tube machine blades, woodworking blades, forestry machinery blades, etc. Features 1) less knife consumption costs. 2) Strictly quality control for the excellent valve. 3) High precision, high intensity. 4) Excellent hardness, small thermal deformation. 5) Matched to their applications. 6) Reduce unsurpassed edge quality. 7) Increased blade durability and reduced retooling time. 8) Excellent cutting quality, stable and reliable cutting performance. Tungsten Carbide Brazed Tips

The carbide brazed tips are used as external turning, boring and grooving tools, used for making twist drills and straight groove drills Material: high virgin raw material with submicron and average grain size. Tolerance: strict tolerance extent control Grades: various for choice: YG6, YG10, YG15, YG20C, etc. Physical performance: high hardness and impact toughness, very good mechanical & chemical stability. Like it? Share it!More by this author |