What Is The Tungsten CarbidePosted by summer on March 11th, 2021

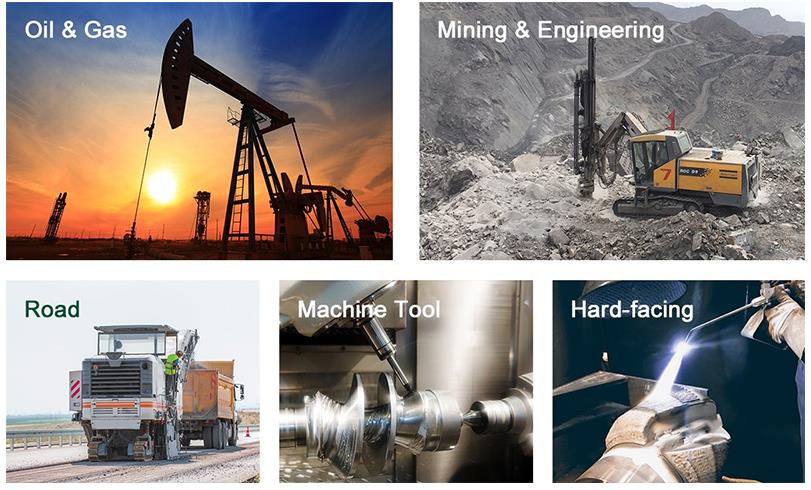

Tungsten carbide is an alloy material made of hard compounds which are consist of refractory metals and bonding metals, through powder metallurgy. Carbide parts have a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance, especially its high hardness and wear resistance, which remains basically unchanged even at a temperature of 500°C. It still has a high hardness at 1000°C. The development history of tungsten carbide In 1923, Schroeter who is from Germany added 10% to 20% of cobalt to tungsten carbide powder as a binder and invented a new alloy of tungsten carbide and cobalt. The hardness is second only to diamond, which is the first artificially made first cemented carbide in the world. When cutting steel with a tool made of this alloy, the cutting edge will wear out quickly, and even the cutting edge may crack. In 1929, Schwarzkov, from the United States, added a certain amount of compound carbide of tungsten carbide and titanium carbide to the original composition for improving the performance of the tool in cutting steel. This is another achievement in the development history of tungsten carbide. In the past two decades, coated cemented carbide has also come out. In 1969, Sweden successfully developed a titanium carbide-coated tool. The matrix of the tool is tungsten-titanium-cobalt cemented carbide or tungsten-cobalt cemented carbide. The thickness of the surface titanium carbide coating is only a few microns, but compared with the alloy tools of the same brand, The service life is extended by 3 times, and the cutting speed is increased by 25% to 50%. The fourth generation of coated tools appeared in the 1970s, which can be used to cut difficult-to-process materials. Wide applications of tungsten carbide Tungsten carbide is widely used as tool materials, such as turning tools, milling cutters, planers, drills, boring cutters, etc., for cutting cast iron, non-ferrous metals, plastics, chemical fibers, graphite, glass, stone and ordinary steel, and can also be applied for cutting hard-to-process materials such as heat-resistant steel, stainless steel, high manganese steel, tool steel, etc. It is used to manufacturing cutting tools, cobalt tools and wear-resistant parts, and is widely applicable in the military industry, aerospace, mechanical processing, metallurgy, petroleum drilling, mining tools, electronic communications, and other much more fields.

Carbide products have high hardness, high strength, excellent wear resistance and corrosion resistance and have been widely used in various industries. The excellent material properties of tungsten carbide make it become more and more important tool materials. Like it? Share it!More by this author |