What Is A Solventless LaminatorPosted by jessie on June 9th, 2021 Solvent-free composite has a wide range of applications. With the advantages of environmentally friendly, hygiene, high efficiency, the solventless laminator is especially applied for the flexible packaging industry.

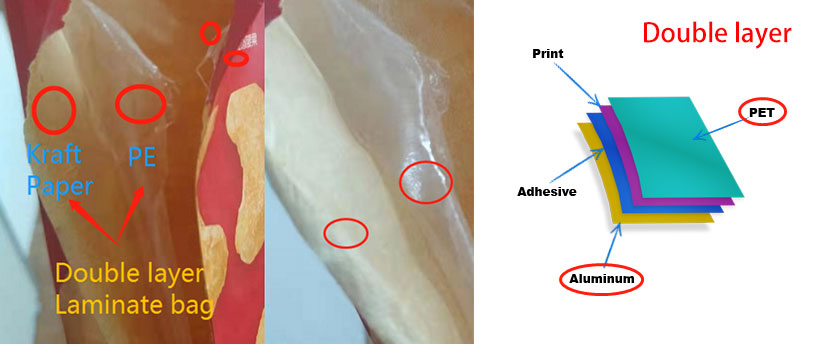

Solventless lamination is a method for the composite of two or more substrates using a solvent-free adhesive. The solventless laminator is the equipment which can be applied for a solvent-free adhesive composite. Composite substrates mainly include BOPP, PET, NYLON, CPP, PE, VMPET, VMCPP, PVC, aluminum foil, paper, etc. Types of solventless laminator There’re three types of solventless laminator including types of exclusive solvent-free, the combination of solvent-free and dry compound, multifunctional combination. Exclusive solvent-free laminator is only used for solventless composite, once molding with two-layer structure or three-layer structure. It can be classified into types of manual roll changing and automatic roll changing. The equipment adopting the combination techniques of solvent-free and dry compound can be used for solventless composite and the coating unit can be switched. This type of equipment can be connected with two machines, thereby achieving a one-time molding of three-layer structure. For example, the first machine produces PET / AL adopting a dry compound method and the second machine can complete the composite of PET / Al and PE using a solventless method. The Multi-function type equipment can achieve solventless, dry compound, PVDC coating, cold sealing positioning coating, hot melt adhesive coating, reverse printing, etc, through switching coating units. Work Principle Of Solventless Laminator The mostly used solventless laminator has a structure of two-layer composite, a single station unwinding, which mainly constitutes of an unwinding unit and coating unit as a first-layer, and an unwinding unit, a composite unit, a rewinding unit. The structure of the solventless laminating machine includes a two-roller device, a winding device, and solvent-free adhesive coating composite equipment. The outstanding feature is that after entering the composite through a special coating device, it is not necessary for drying. The solventless composite machine satisfies the requirement of a solvent-free adhesive coating,which is a significant difference from the solvent drying compound equipment. The solvent-free machine has precise control for the temperature of the coating equipment, relying on the adjustment of temperature and the viscosity of the adhesive for promoting the coating application. It is equipped with a closed-loop tension controller which can strictly control the winding tension.

For a more professional introduction, please visit the article page on why choose a solventless laminator. Like it? Share it!More by this author |