The future for constructing a fish feed production line

Posted by Misty Richi on October 18th, 2022

Considering that feed automation, international feed manufacturing has actually gotten in a brand-new phase, as well as the worldwide feed outcome has actually been climbing. What are the advantages of utilizing the fish feed production line to generate fish feed pellets on your own?

Presently, the full-price feed of the majority of cultured fish is difficult granular, so it is bothersome to include some ingredients or illness avoidance medicines in the process of usage. When making use of the fish feed assembly line to make pellets, different feed ingredients and also illness avoidance medications can be included time according to the requirements of cultured fish, so regarding additional boost the feed high quality, boost the feed conversion price as well as enhance the avoidance as well as therapy of fish conditions.

The related cases are: Floating Fish Feed Plant In Iran

In various areas, various farmers have various equipping settings, and also there are fantastic distinctions in the called for feed nourishment degrees. The full-price feed created by many makers primarily creates the feed formula according to the dietary requirements of the basic fish, and also seldom takes into consideration the dietary requirements of the restricted fish. Making use of self-made feed can be based upon the reproducing setting and also the equipping problems of various varieties of fish, Taking right into account the dietary demands of the restricted fish as well as the primary fish, the proper feed formula is created to fulfill the dietary requirements of the fish.

With the development of fish, their dietary demands are additionally altering. It is additionally needed to readjust the dietary degree of feed. Just this way can we not just fulfill the expanding demands of fish whatsoever phases however additionally successfully lower the feed expense.

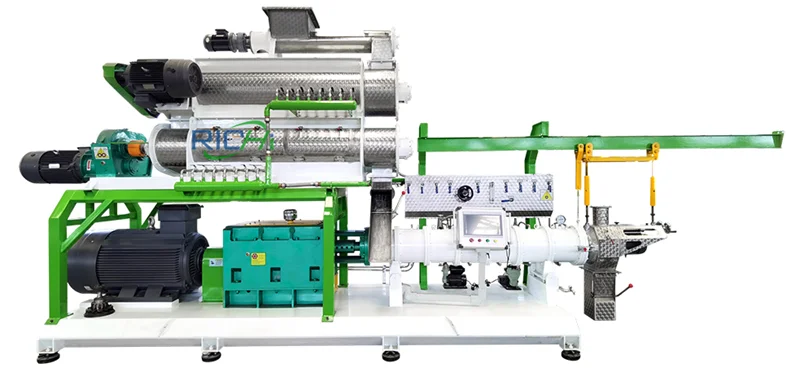

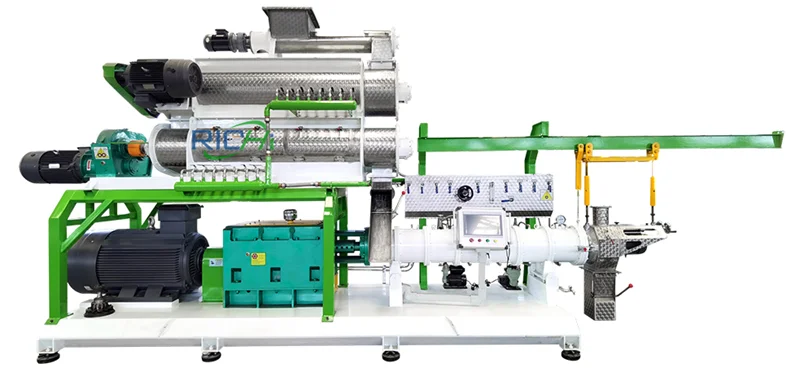

The primary tools of the fish feed production line is a floating fish feed extruder machine. The fish feed extruder is a twin screw extruder, which is primarily made use of for the manufacturing and also handling of state-of-the-art water feed pellets as well as family pet feed pellets, consisting of the handling of thick formula products.

The fish feed pellet extruder can generate sinking as well as drifting fish feeds according to the feeding features and also routines of fish. The fish feed pellet extruder can generate water feeds with various pellet dimensions as well as forms.

The temperature level and also stress problems of extrusion handling are more powerful than granulation as well as growth. It is the favored handling approach for marine feed as well as family pet feed, which can much better enhance the food digestion and also usage price of these pet feeds. This can be accomplished by a fish feed extruder.

With the fast advancement of the tank farming sector, specifically the expanding financial advantages of tank farming, a range of water feeds such as puffed pellets as well as difficult feed pellets came right into being. As fish have little intestinal tracts, and also inadequate food digestion and also absorption, marine feed handling innovation is much more requiring than the handling of animals and also fowl feed.

The manufacturing of premium fish feed have to rely upon affordable and also clinical handling modern technology, and also make it integrated with innovative, trusted, as well as steady handling equipment. Hereof, the option of handling devices for the fish feed assembly line is especially essential.

( 1 )The option of squashing tools

When generating regular fish feed, the dimension of its raw products is called for 40-60 mesh. When creating the unique marine pellet feed (shrimp feed, eel feed, turtle feed, and so on), the dimension of raw products have to get to even more than 80 mesh.

RICHI Machinery has this mini crumbler. The mini crumbler is extensively made use of in the squashing of basic materials of fish feed. The crucial components are all imported, as well as it is simple to preserve as well as run.

( 2 )The choice of the pelletizing devices

For the manufacturing of fish feeds, a high level of pasting as well as security in water is called for, so conditioning is crucial. In needed wetness and also temperature level, the only method to get this is expanding the conditioning time. One of the most usual devices is the multi-layer conditioner prior to pelleting.

RICHI Machinery can offer you with a fish feed production line with a three-layer conditioner. Inside the conditioner, the raw product is totally exposured to the saturated completely dry heavy steam, to come to be fully grown, pasted, and also decontaminated.

( 3 )The option of tools for generating drifting fish feed

Feed puffing innovation is mostly utilized in the manufacturing of unique water feed, pet dog feed, and also various other pet feed. Along with the benefits of the basic full-price pellet feed, the puffed feed additionally has the capacity to enhance the digestive system absorption price of fed pets and also can successfully protect against pet digestion system conditions.

The fish feed extruder of a total fish feed production line is ideal for the handling of numerous drifting and also sinking water feed, nursing pig feed, family pet feed, and so on. To create fish feeds and also get top notch feeds of various types that fulfill the demands, one must select the relevant tools according to the types they generate. RICHI Machinery has its very own manufacturing facility and also expert manufacturing tools.

Because feed automation, international feed manufacturing has actually gotten in a brand-new phase, as well as the international feed outcome has actually been increasing. The fish feed extruder is a twin screw extruder, which is primarily made use of for the manufacturing and also handling of state-of-the-art water feed pellets and also pet dog feed pellets, consisting of the handling of thick formula products. It is the favored handling technique for marine feed as well as pet dog feed, which can much better boost the food digestion and also use price of these pet feeds. When creating the unique water pellet feed (shrimp feed, eel feed, turtle feed, and so on), the dimension of raw products need to get to even more than 80 mesh. The fish feed extruder of a full fish feed production line is ideal for the handling of different drifting and also sinking water feed, nursing pig feed, animal feed, and so on.

More information is on the website: RICHI Machinery

Shrimp Feed Pellet Machine

Or you can contact:

Whatsapp: +86 18574103366

Email: enquiry@richipelletmill.com