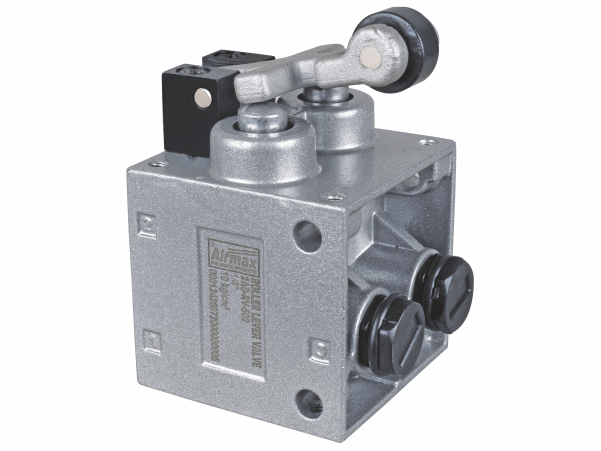

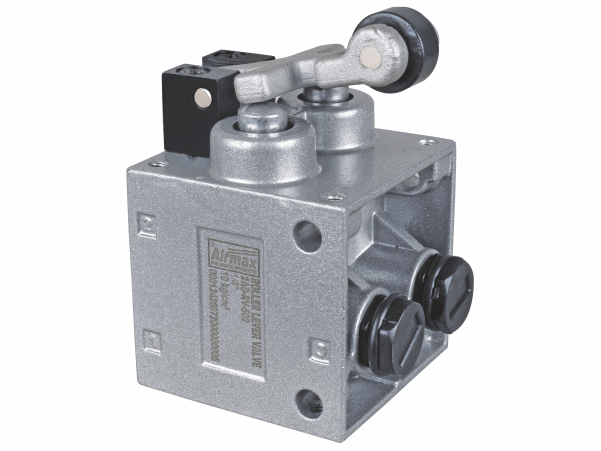

Pneumatic Roller Valve An Overview

Posted by Airmax Pneumatics on May 11th, 2023

Introduction

Pneumatic roller valves are control devices that regulate the flow of fluids within a pneumatic system. These valves use compressed air to actuate their internal components, which are designed to either open or close the valve's flow path. Pneumatic roller valves are essential components in various industries, including manufacturing, automotive, and construction.

What is a Pneumatic Roller Valve?

These valves use compressed air to actuate their internal components, which are typically designed to either open or close the valve's flow path. Pneumatic roller valves are used in a wide range of applications, from simple on/off control to precise flow regulation.

How Does a Pneumatic Roller Valve Work?

A pneumatic roller valve typically consists of a valve body, actuator, and internal components. The valve body contains the fluid passage, which can be opened or closed by the internal components. When compressed air is applied to the actuator, it moves the internal components of the valve, either opening or closing the fluid passage. The amount of air pressure applied to the actuator determines the position of the internal components and therefore the flow of fluids through the valve.

Regulation of fluid flow in pipelines and process control systems

Control of pneumatic motors in industrial and automotive applications

Control of air supply to pneumatic tools and equipment

Regulation of fluid flow in irrigation and sprinkler systems

Control of pneumatic systems in HVAC applications

Types of Pneumatic Roller Valves

They typically have two positions: open or closed.

Control valves: These valves are designed for more precise control of fluid flow. They can have multiple positions, allowing for fine-tuned regulation of flow rates.

Solenoid valves: These valves use an electromagnetic coil to control the position of the internal components.

Benefits of Using Pneumatic Roller Valves

Simple design: They also have fewer components than other types of valves, reducing the likelihood of failure.

Fast response time: Pneumatic roller valve can respond quickly to changes in pressure, allowing for precise control of fluid flow.

Factors to Consider When Choosing a Pneumatic Roller Valve

Flow rate: The valve must be sized correctly to ensure that it can handle the required flow rate.

Operating pressure: The valve must be able to operate within the required pressure range.

Valve type: The valve type must be selected based on the application's specific requirements, such as on/off control or precise flow regulation.

Installation and Maintenance of Pneumatic Roller Valves

Proper installation and maintenance are essential for ensuring the optimal performance of pneumatic roller valves.

Clean the valve regularly to prevent contamination.

Replace any damaged or worn components promptly.

Follow the manufacturer's recommended maintenance schedule.

Common Issues and Troubleshooting

They can be addressed by replacing the damaged components.

Sticking: Valves may stick due to contamination or wear.

Failure to operate: This can occur due to issues with the actuator or internal components.

Best Practices for Pneumatic Roller Valve Usage

Clean the valve regularly to prevent contamination.

Use compatible fluids.

Avoid exposing the valve to harsh environments or extreme temperatures.

Use the correct valve type for the application.

Innovations in Pneumatic Roller Valve Technology

Future Trends and Developments

Conclusion

Pneumatic roller valves are essential components in many industrial applications, offering reliable operation, simple design, and fast response times. Proper installation and maintenance are crucial for ensuring optimal valve performance, and advancements in technology are expected to lead to the development of more advanced and efficient pneumatic roller valves in the future. At Airmax, we specialize in providing high-quality pneumatic industrial applications. Choose Airmax for all your pneumatic roller valve needs, and experience the benefits of high-quality components, exceptional service, and unparalleled expertise.