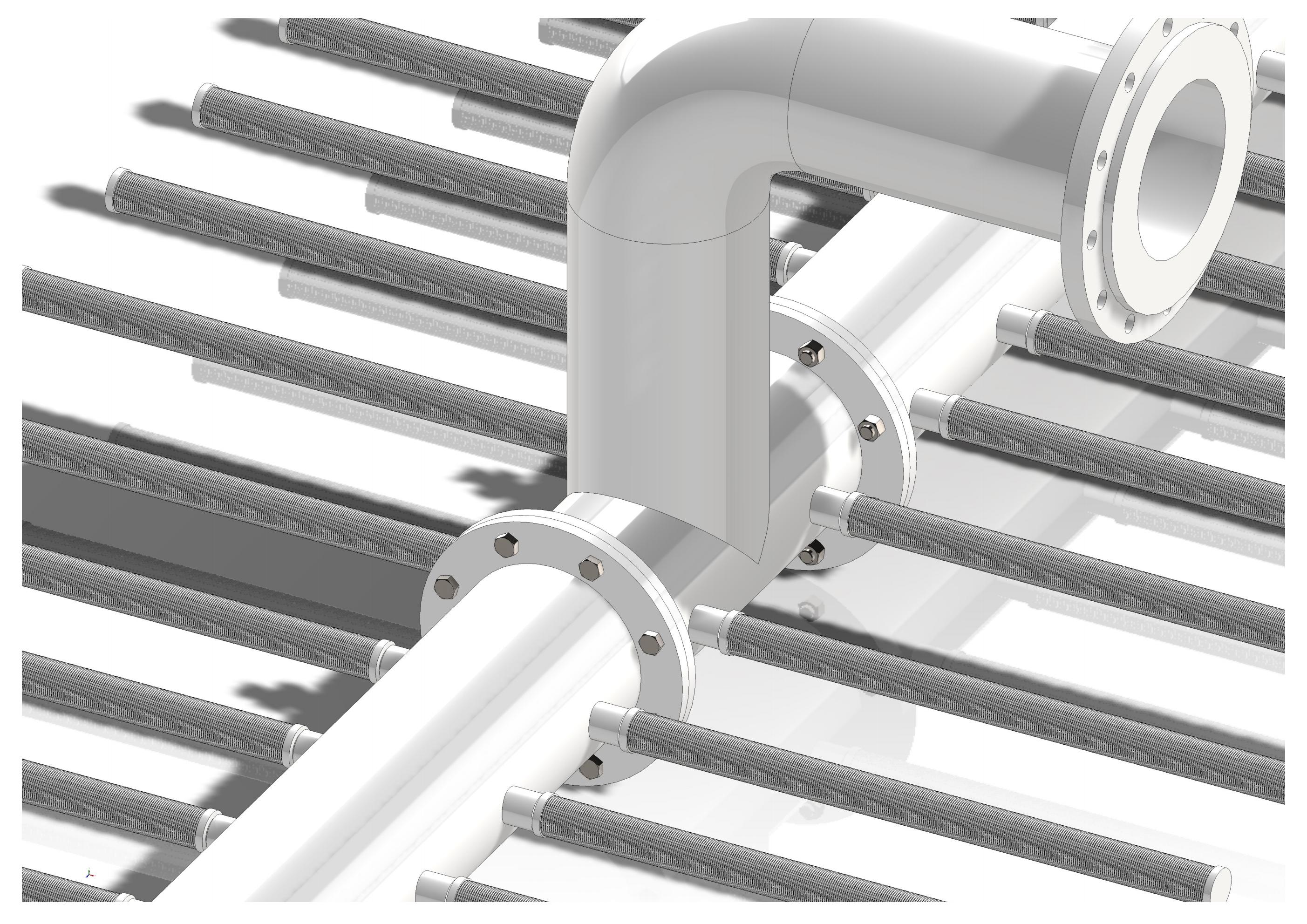

Tower Internals Technology and ProductsPosted by YUBO Filtration on March 11th, 2024 Optimizing tower internals is crucial for achieving maximum mass transfer efficiency in various industrial processes. Our comprehensive range of tower internals includes liquid distributors, bed limiters, support plates, spray nozzles, and collector trays. Understanding the layout and functionality of tower internals is essential for selecting the right components tailored to your specific application. Tower Layout and Operation:A tower's primary function is facilitating the interaction between liquid and gas, promoting mass transfer. Utilizing diverse packing media and distribution channels increases the surface area for efficient contact between the liquid and gas phases. Tower internals play a pivotal role in ensuring the uniform distribution of liquid and gas throughout the tower, influencing the overall performance of absorption or distillation processes. What Are Tower Internals?Each of the tower internals works to aid in evenly distributing liquid and gas for maximum mass transfer. Each component plays a vital role and must match the needs of the pressure, liquids and gases it works with. The following are common tower internals necessary for efficient operation: 1. Liquid Distributor/RedistributorThis pipe-type distributor accommodates multiple branch pipes with bottom orifices, ideal for pressurized liquid feeds and dispersed phase distribution in extraction columns.

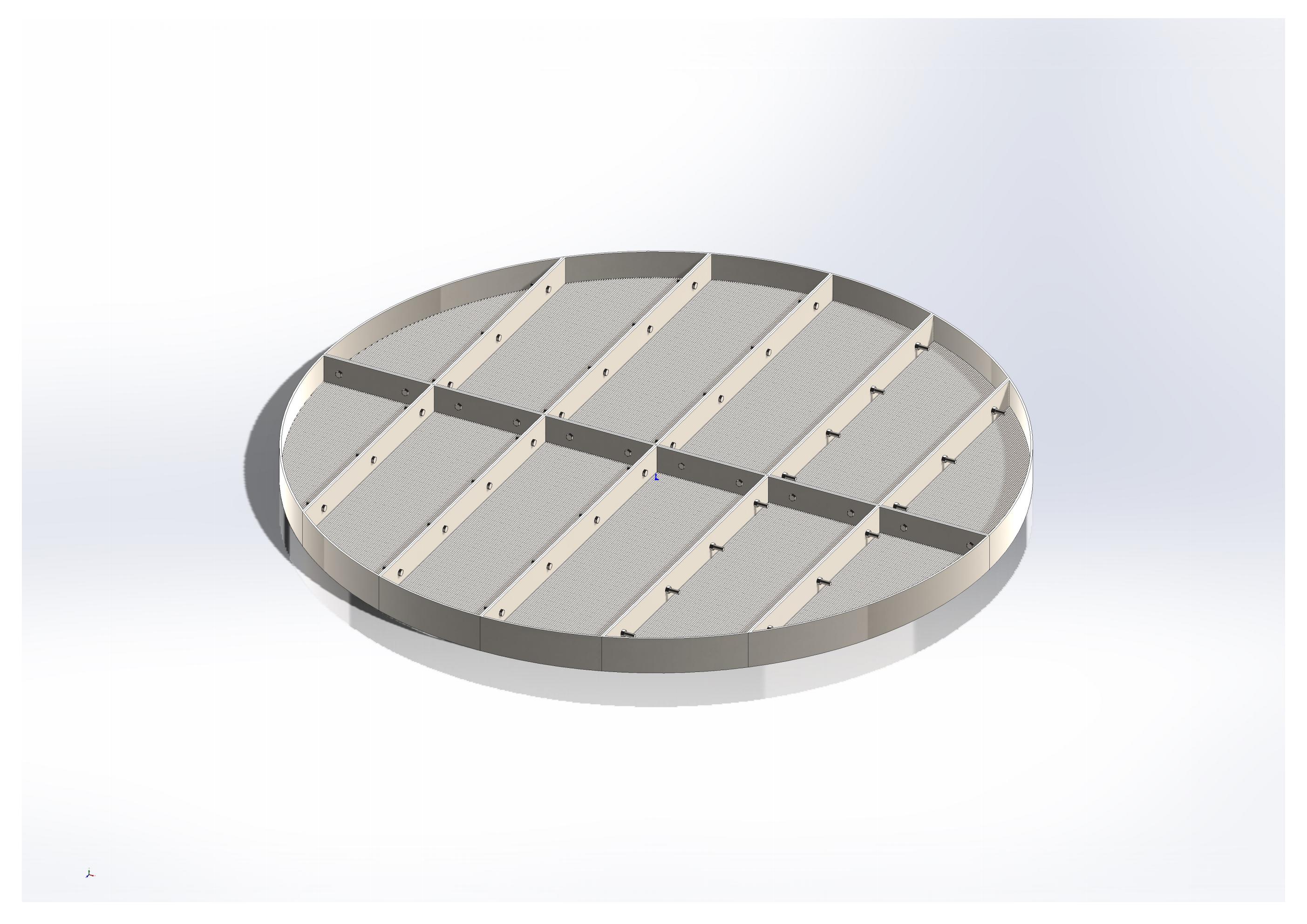

2. Supporting GridWell-designed supporting grids are versatile and capable of handling random or structured packing materials. They provide maximum open area, support packing beds of any height, and contribute to overall tower performance.

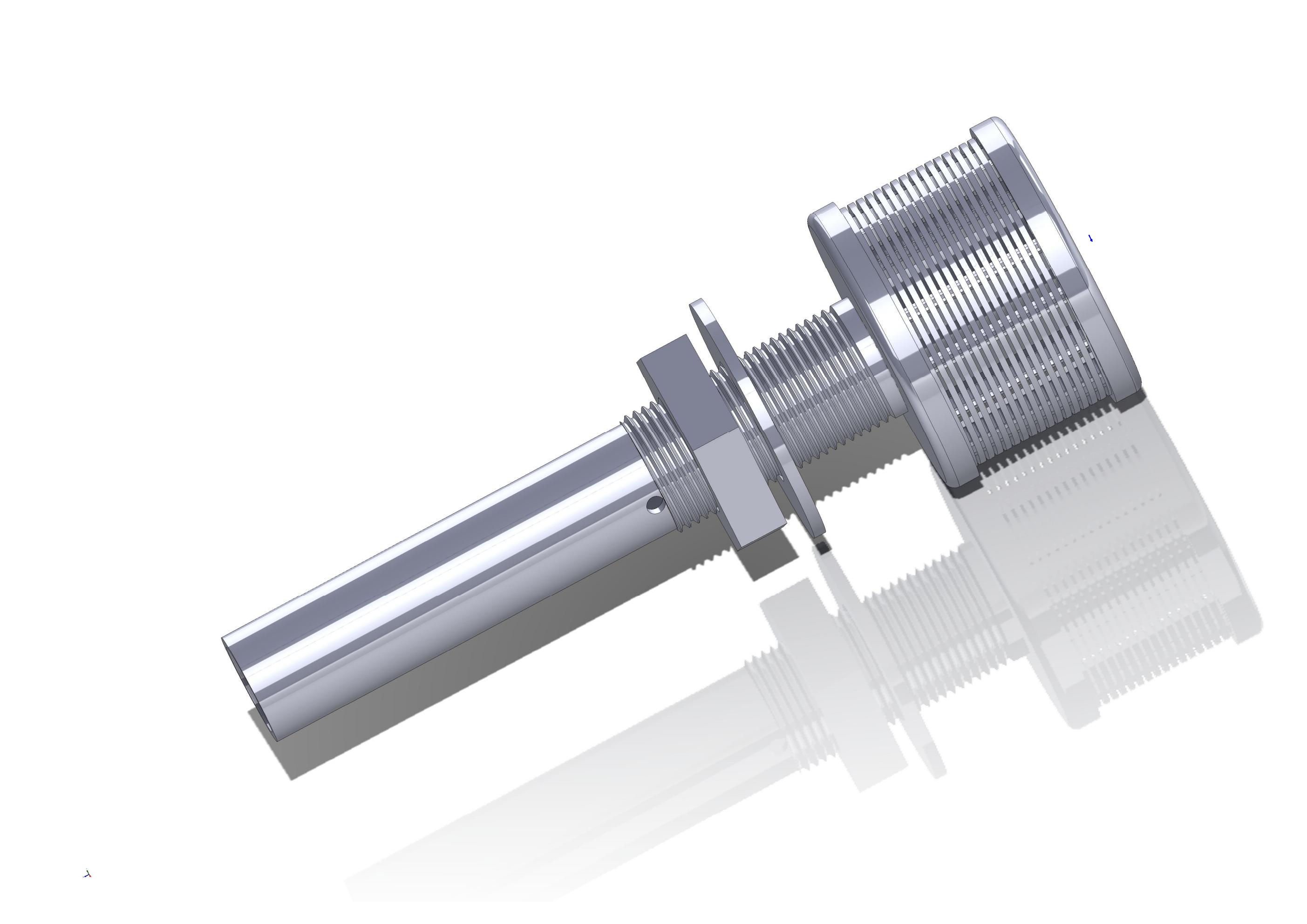

3. Spray NozzlesOur range of full spray nozzles offers various angles and flow rates to meet specific application requirements, ensuring precise and efficient liquid distribution.

4. Catalyst Support PlateSpecifically designed to bear the weight of catalysts, support materials, and oil, this component withstands pressure drops across the catalyst bed during the entire catalyst cycle. Tower Operation Overview:The general tower layout involves a liquid inlet at the top and a gas inlet at the bottom. Gas ascends through a distributor and packing material to mix with the descending liquid, creating optimal conditions for mass transfer. Supports maintain the integrity of each packing layer, while a liquid redistributor in the middle prevents liquid accumulation along the tower walls. Selecting the Right Tower Internals:Choosing the appropriate tower internals is critical for matching your application's specific needs of pressure, liquids, and gases. Our team can assist you in selecting the ideal tower internals for your unique requirements, ensuring enhanced mass transfer efficiency. Contact Us Today:If you are unsure about which tower internals suit your needs, we are here to help. Feel free to reach out for expert guidance or request a quote for our high-quality tower packing materials and other components. Enhance your tower's performance with the right internals for optimal mass transfer efficiency. Like it? Share it!More by this author |