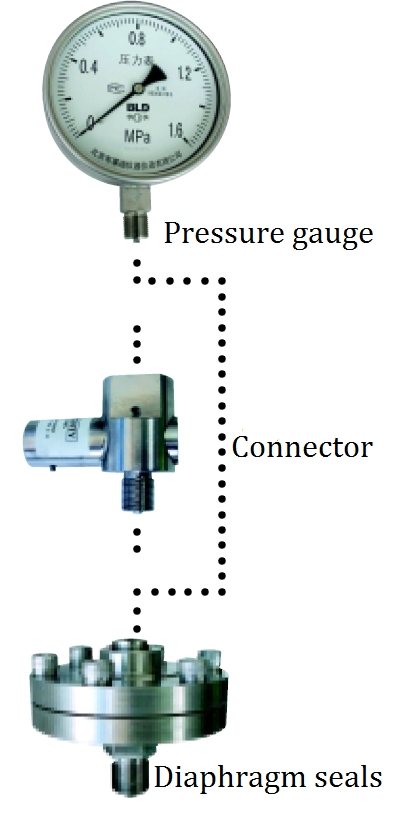

Diaphragm Pressure Gauge- Capillary Type Pressure GaugePosted by jsbsheng on June 19th, 2017 Diaphragm Pressure Gauge OverviewDiaphragm pressure gauge (chemical seals pressure gauge) is composed of a conventional pressure gauge, connector and a diaphragm seal. This combination enables a general industrial purpose pressure gauge to measure media of strong corrosion, high temperature, and high viscosity, containing suspended matter or crystallizing. Diaphragm pressure gauges are universally used in petrochemical, alkali, and chemical fiber, pharmaceutical, metallurgical, and food industries. We are a China Diaphragm pressure gauge manufacturer, we supply cheap custom diaphragm pressure gauge but still with robust and stable quality. Custom diaphragm seal pressure gauge, such as sanitary pressure gauge, capillary type pressure gauge, flanged pressure gauge, flush mount pressure gauge, high temperature pressure gauge.,etc. welcome to send your drawings or your technical specifications for pressure gauge diaphragm type. We will design for you.

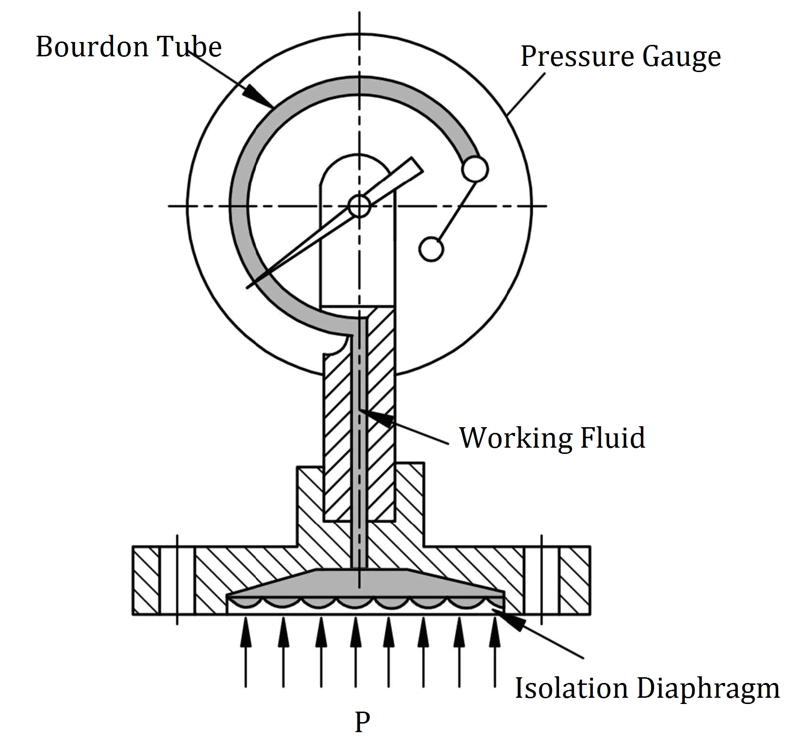

Configuration Principle of Diaphragm Pressure GaugeThis illustration shows the operating principle of the pressure gauge with diaphragm seal. The diaphragm is deflected by the pressure of medium P, and an equivalent pressure P is generated. With transmitting through working fluid, the pressure P. deflect the elastic element of a pressure measuring instrument which thereafter shows the pressure value.

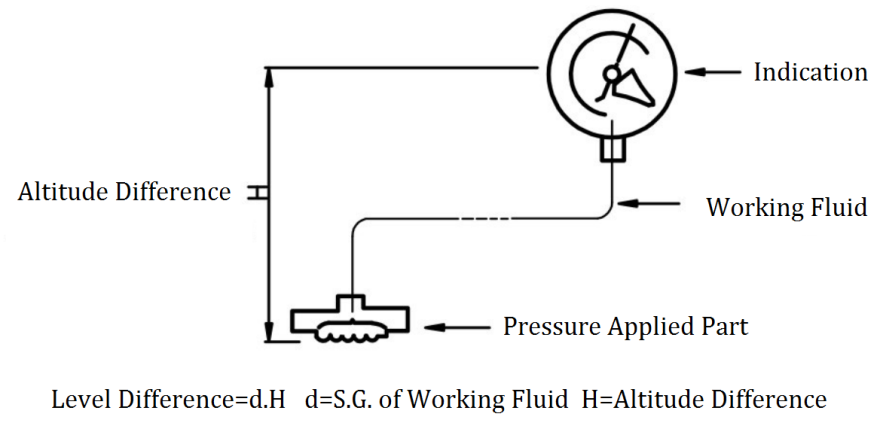

Level Difference of Diaphragm Pressure Gauge Seals LiquidWhen a sealed diaphragm pressure gauge is mounted with pressure gauge and diaphragm seal at different positions, the effect of level difference should be taken into consideration (especially for a diaphragm gauge with capillary).As the illustration shows, with a S.G of the working fluid at approx.1, and level difference of 1m, the pressure difference of Diaphragm manometer is approx.0.001Mpa.

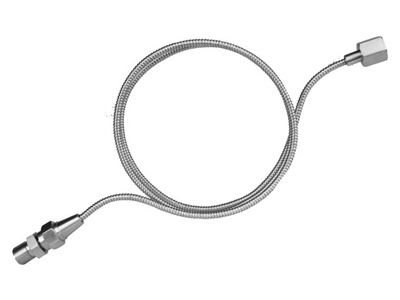

Temperature Influence of diaphragm pressure gaugeThe temperature influence of a pressure gauge diaphragm type is relative to expansion coefficient of the seals working fluid, rigidity of the diaphragm, and temperature of pressed part. When working temperature deviates from 20±5°C,the indication varies within 0.1%/°C for rigid system, and within 0.1+0.025L%/°C (L-length of capillary in m.) for flexible system (remote mounting). Diaphragm manometer is filled with suitable working fluid according to different operating conditions.

Or other special working fluid

Corrosion-Proof Properties of diaphragm pressure gaugeOur Diaphragm Seal Pressure Gauge satisfies customer’s requirements of both environmental conditions and flow conditions (corrosive media) based on its significant corrosion-proof properties. Choose various diaphragm pressure gauges combined with appropriate separator according to environmental conditions. Choose material of chemical seal diaphragm and housing compatible with corrosive media.

①.DiaphragmMaterial: SUS316,SUS316L,Monel (Cu30Ni70),Hastelloy(HC276), Tantalum (Ta), Fluoroplastic (PTFE)coated

②.BodyMaterial: 1Cr18Ni9Ti,SUS316, SUS316L,Fluoroplastic (F4), Fluoroplastic Coated Stainless Steel

③.GasketMaterial: Nitrile Rubber, Viton, Silicone Rubber, Fluoroplastic

Options for diaphragm material

Anti-corrosion materials for diaphragm pressure gauge

Remark:〇-best; △-conditional; ∨-use; ×-no using.

Standard material for Diaphragm manometer is SUS316L,corrosion-proof materials should be applied in normal temperature.

Diaphragm Pressure Gauge Model Selection

Example of Diaphragm Pressure Gauge

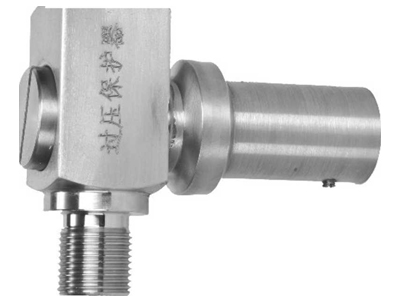

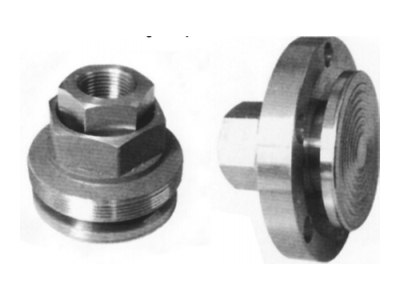

Connectors of Example of Diaphragm Pressure Gauge

Pressure Gauge Diaphragm Seals

Like it? Share it!More by this author |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||