How To Make Precision Injection Molds?Posted by imoldmaking on January 3rd, 2020 Precision injection mold is a kind of plastic injection molding method which requires precision mold and precision machines. It allows the production of high-precision components and parts. In this article, we will discuss the concept of precision mold and its advantages. Controlling the way molten plastic fills and cools down in a plastic injection mold to develop a component is a progressing science. Vigorous injection molding companies are injecting new energy into this industry regularly, to enhance the top quality and the precision of molds that consequently will certainly enhance the usefulness of components being made. Dividing the part to be developed into basic teams assists lessen molding obstacles as well as improve precision mold.

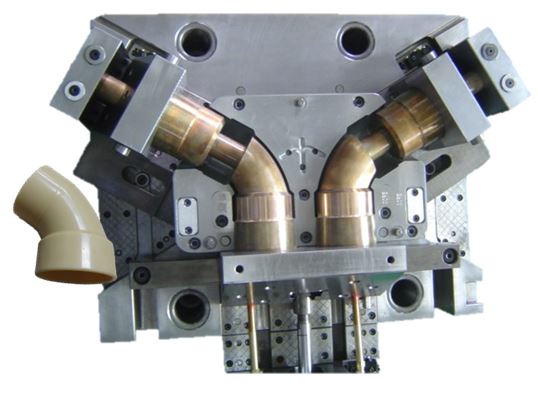

The Concept of Precision Injection Molding The precision injection mold is a kind of injection molding approach which is challenging to satisfy the needs of the injection molding machine and standard injection molding process. The principle of precision injection molding is mostly distinct from "conventional injection molding". It is based upon the fast growth of polymer products and utilizes specific plastic parts to replace high-precision metal parts in the instrument and electronic devices field. The principal is the perpetual precision of the product size, as well as the two, are the repeatable precision of the product quality. The precision injection molding is essentially established from the repeating precision of the product size. Nonetheless, due to the distinct characteristics and refining innovation of numerous products, the precision of the plastic parts can not be corresponded with the precision of the metal components. The mold of molded products is a crucial problem to conclude whether the item can satisfy the style specifications and precision injection. Injection molding is made with the aid of state-of-the-art modern technology. Expert injection molding companies and manufacturers produce molds that satisfy the demands of buyers. The process uses applied science and assessment procedures that are automated. The injection molding companies have different precision molding techniques that are compiled within a controlled setting. Quality assurance As for quality control goes, the precision mold dimension gets on the listing of the most important things. The precision dimension of a trustworthy manufacturer is virtually flawlessly precise. The quality control approaches, as well as the advanced machinery, makes sure that the requirements of the clients are met. Precision Mold Machine Heat can influence the viscosity of hydraulic oil in mold makers which might produce velocity as well as stress deltas in the molding cycle. Such variant triggers dimensional disparity from injection to injection in the molding process. To minimize these impacts, Injection molding companies utilize what is widely considered one of the most specific and precision injection molding machines on the planet. All electrical molding devices use exceptionally exact servo-electric motors without any of the variability inherent in hydraulic mold makers to accomplish repeatability within microns. Dong Guan Gui Cheng Mold Co. Ltd. (GC PRECISION MOLD) is one of the leading manufacturers of Precision molds in China. We work our best to ensure the most distinguished quality plastic molds are serviced in the shortest delivery time to clients on approval. For more information about our manufacturing services, head over to our official website. Like it? Share it!More by this author |